Mobile chippers&shredders

These knives for drum and disc wood chippers are used in the production of wood chips in the paper and furniture industries and in the production of biomass. They are durable, accurate and can withstand the toughest conditions. We produce them for the whole world using advanced technology, using high-quality alloy steels, and based on ninety years of industry know-how. You can choose the best-selling knives and parts for chipping machines in our e-shop. We will be happy to offer you the rest on request.

In addition to chipper knives, we also produce counter-knives, breakers, knife and counter-knives holders, sieves for chipping machines, infeed rollers, and other parts. On request, we also supply drums or rotors of chippers, and we provide their overhaul. All these products are used to produce wood chips, which then produce paper, pulp, biomass, pellets, artificial fertilizer or boards for the furniture industry. They can also be used for wood recycling, chipping soft and frozen wood, mixing hard tropical wood and waste wood or sawmill residues.

Our chipper knives and other accessories in the woodworking industry can be used in chipping machines of leading world brands such as Albach, Eschlböck Biber, Mux-Max, Doppstadt, Bruks, Kesla, Vermeer, Bandit, Vecoplan, Rudnick, Erjo, Ferrari, Maier, Pallmann, Hombak and Greenmech.

We produce these wood chippers from chipper 5 and chipper 8 material, with a blade angle and hardness according to the customer's needs. We can also design a knife from a different material and with a different hardness to meet special requirements and the raw material being processed.

A large part of worn or damaged rotors do not need to be replaced with new ones – just overhaul them and extend their service life. We have been dealing with overhauls since 2012, we have the necessary equipment and satisfied clients around the world. If you send us a photo with visible wear or damage to a particular part or unit, our technicians will assess the possibilities of overhaul and our sales department will send you a quote.

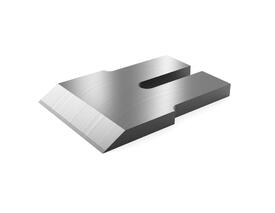

Knife 200x225x18 CH8

30°/28°

Knife 168x235x20 CH8

34°/30°

Knife 124x192x18 CH8

33°/27°

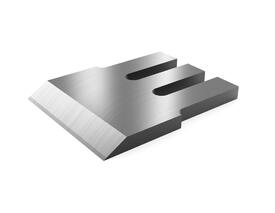

Knife 233x245x20 dr. 26 CH8

30/34° 2xdr. 26

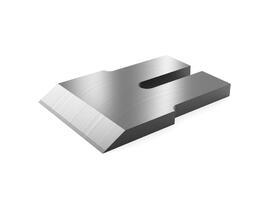

Knife 200x225x18 30°/28° CH5

30°/28°

Knife 168x235x20 CH5

34°/30°

Knife 200x350x25 CH8

28°/26°

Knife 200x245x20 CH8

34°/30°

Knife 200x350x25 CH5

28°/26°

Knife 852x185x16/15 CH8

33°

Knife 164,5x235x20 CH5

35°/29°

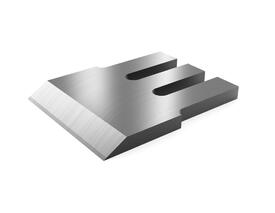

Knife 233x245x20 CH8

34°/30° 3xdr.29

Knife 164,5x235x20 CH8

35°/29°

Knife 200x250x18 CH8

30°

Knife 140x230x18 slot 125mm CH8

35°/30°

These knives for drum and disc wood chippers are used in the production of wood chips in the paper and furniture industries and in the production of biomass. They are durable, accurate and can withstand the toughest conditions. We produce them for the whole world using advanced technology, using high-quality alloy steels, and based on ninety years of industry know-how. You can choose the best-selling knives and parts for chipping machines in our e-shop. We will be happy to offer you the rest on request.

In addition to chipper knives, we also produce counter-knives, breakers, knife and counter-knives holders, sieves for chipping machines, infeed rollers, and other parts. On request, we also supply drums or rotors of chippers, and we provide their overhaul. All these products are used to produce wood chips, which then produce paper, pulp, biomass, pellets, artificial fertilizer or boards for the furniture industry. They can also be used for wood recycling, chipping soft and frozen wood, mixing hard tropical wood and waste wood or sawmill residues.

Our chipper knives and other accessories in the woodworking industry can be used in chipping machines of leading world brands such as Albach, Eschlböck Biber, Mux-Max, Doppstadt, Bruks, Kesla, Vermeer, Bandit, Vecoplan, Rudnick, Erjo, Ferrari, Maier, Pallmann, Hombak and Greenmech.

We produce these wood chippers from chipper 5 and chipper 8 material, with a blade angle and hardness according to the customer's needs. We can also design a knife from a different material and with a different hardness to meet special requirements and the raw material being processed.

A large part of worn or damaged rotors do not need to be replaced with new ones – just overhaul them and extend their service life. We have been dealing with overhauls since 2012, we have the necessary equipment and satisfied clients around the world. If you send us a photo with visible wear or damage to a particular part or unit, our technicians will assess the possibilities of overhaul and our sales department will send you a quote.