Knives and parts for sawmills

These knives and parts for wood sawmill machines are used in sawmill operations for primary round timber processing and board production. We produce them from high-quality alloy steel using advanced technology and know-how gained over 90 years in the industry. This makes our sawmill knives and parts durable and reliable, and are used by people in the woodworking industry around the world. The best-selling of them can be found in the e-shop, the others are available on request.

In addition to sawmill knives, you will find knives for reducing the end of the trunk, monolithic debarking knives with SK blades, chipping knives and profiling knives. As accessories for sawmill knives we produce chip breakers, knife holders and other fasteners. Our sawmill knives for the woodworking industry are part of machines of leading world brands such as Linck, EWD, Baljer-Zembrod, Bruks, Hombak or Lindex Sawmill Tools.

Knives and accessories for sawmills are manufactured from chipper 5 and chipper 8 using atmospheric and vacuum heat treatment and cryogenic methods that guarantee maximum durability, accuracy, and long-term reliability of products even in the most demanding conditions.

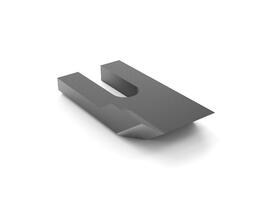

Knife 45x105x8

edge 31°; slot 17mm; 2x side edge 45°; M5

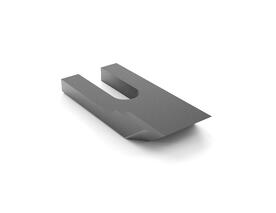

Knife 35x75x12,25 Left

edge 38°; slot 14mm

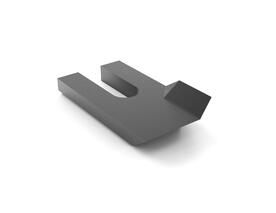

Knife 35x75x12,25 right

edge 38°; slot 14mm

Knife 41x105x8 31°

Edge 31°

Knife 76x101x20 right

edge 35°; M16

Knife 76x101x20 left

edge 35°; M16

Knife 74,5x94,5x20 left

edge 45°; M16

Knife 74,5x94,5x20 right

edge 45°; M16

Knife 47,8x62x13,8 right

profile 110°/34,2mm; hole D12,3/ countersink D23; angle 30° opposite angle 7°

Knife 41x105x8 35°

Edge 35°

Knife 76x35x20

edge 32°; slot 15/24,5mm at an angle 2°

Knife 47,8x62x13,8 left

profile 110°/34,2mm; hole D12,3/ countersink D23; angle 30° opposite angle 7°

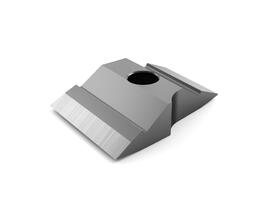

Knife 289x115x12 31° + 29°/34°

main edge 31°; side edge 29°/34°; 3x slot 18mm; 2x M6

Knife 73,3x94,5x20 right

edge 35°; M16

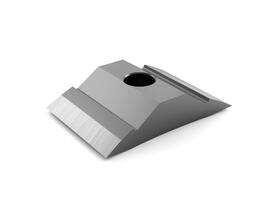

Knife 289x115x12 31° + 48°/37°

main edge 31°; side edge 48°/37°; 3x slot 18mm; 2x M6

Knife 60x54x40 D18/D26

butt reducer / debarker; 4x blade; 2x R25; hole D18/ countersink D26

Knife 92x105x12

edge 32°; 2x M6; slot 21mm; 2x chamfer 65°

Knife 40x100x12

2x M6; slot 17mm; edge 33°; 2x chamfer 5,5x45°

Knife 73,3x94,5x20 left

edge 35°; M16

Knife 92x105x12 Standard

edge 32°; 2x M6; slot 21mm; 2x chamfer 65°

Knife 60x54x40 2xD12,5/D20

butt reducer / debarker; 4x blade; 2x R25; 2x hole D12,5/ countersink D20

Knife 44,4x62x13,8

profile 110°/34,2mm; hole D12,3/ countersink D23; angle 30° opposite angle 7°

Knife 60x54x40 2xD12,5/D19

butt reducer / debarker; 4x blade; 2x R25; 2x hole D12,5/ countersink D19

Knife 76x35x20 side angle 1,7°

edge 32°; slot 15/24,5mm at an angle 2°; side edge 1,7°

Knife 25x82x10

edge 30°/45°; M6; 2x chamfer 40°

Knife 39x75x16 right

slot 14mm; M5; edge 37°

Knife 58x79,4x26 left

2x slot with countersink D11,5/D18; edge 33°; opposite angle 3°; 2x M6

Knife 58x79,4x26 right

2x slot with countersink D11,5/D18; edge 33°; opposite angle 3°; 2x M6

Knife 39x75x16 left

slot 14mm; M5; edge 37°

Knife 30x82x10 M6

edge 30°; M6; 2x chamfer 40°

These knives and parts for wood sawmill machines are used in sawmill operations for primary round timber processing and board production. We produce them from high-quality alloy steel using advanced technology and know-how gained over 90 years in the industry. This makes our sawmill knives and parts durable and reliable, and are used by people in the woodworking industry around the world. The best-selling of them can be found in the e-shop, the others are available on request.

In addition to sawmill knives, you will find knives for reducing the end of the trunk, monolithic debarking knives with SK blades, chipping knives and profiling knives. As accessories for sawmill knives we produce chip breakers, knife holders and other fasteners. Our sawmill knives for the woodworking industry are part of machines of leading world brands such as Linck, EWD, Baljer-Zembrod, Bruks, Hombak or Lindex Sawmill Tools.

Knives and accessories for sawmills are manufactured from chipper 5 and chipper 8 using atmospheric and vacuum heat treatment and cryogenic methods that guarantee maximum durability, accuracy, and long-term reliability of products even in the most demanding conditions.