Recycling industry

Filter

Technical support

Not sure what to choose? Get in touch. We usually respond within one business day.

Michael Polster

Your sales representative

+420725916991

polster@pilana.cz

Stator knife middle 233x245x50

Stator knife center

Log in to see price

>500 pcs in stock

Stator knife 500x105x34 T

Stator knife shape T (original shape); 4x slot; angle 0,8°

Log in to see price

>500 pcs in stock

Knife Holder 172,5x119x77 right

Right

Log in to see price

>100 pcs in stock

Clamp knife 60x53x36

1xD 26/42,5;

Log in to see price

>100 pcs in stock

Thread bushing M30 D68x58

For knife 145x145x47

Log in to see price

>100 pcs in stock

Counter knife holder 345x196x72 M30

4x D40/17 ; 2xM30 Hard welding

Log in to see price

>100 pcs in stock

Rotor knife 239,3x66x25

Rotor knife thickness 25mm; 2x M16; angle 14°; 3 teeth

Log in to see price

>100 pcs in stock

Rotor knife 159,3x66x25

Rotor knife thickness 25mm; 3x M16; angle 14°; 2 teeth

Log in to see price

>100 pcs in stock

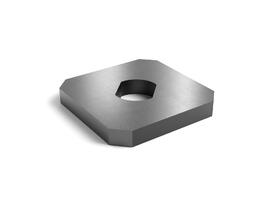

Underplate 110x110x15

D42/33

Log in to see price

>100 pcs in stock

Knife Holder 172,5x119x77 left

Left

Log in to see price

>100 pcs in stock

Underplate 171x77x10

2xD22

Log in to see price

>100 pcs in stock

Rotor knife 208x217x40 Standard

Rotor knife; 3x M16;

Log in to see price

>100 pcs in stock

Rotor knife 800x98x24

Angle 42°, 4xM12x1,25

Log in to see price

>100 pcs in stock

Pressure plate 344x225x59

3xd26/d40 Hard welding

Log in to see price

>100 pcs in stock

Rotor knife 485x100x22 2xM12

Angle 50°, 3x slot 22mm, 2xM12

Log in to see price

>100 pcs in stock